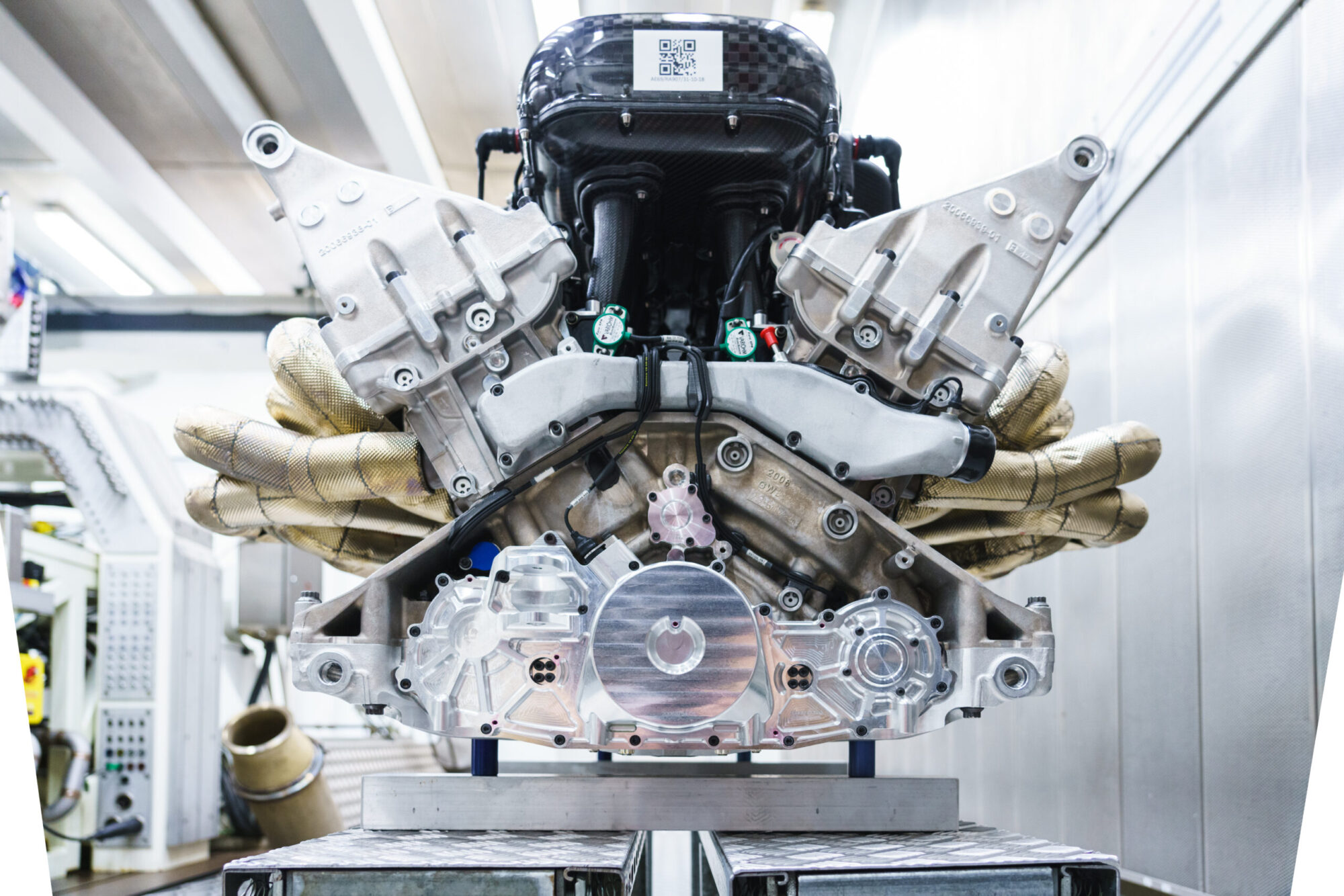

- New naturally-aspirated 6.5-litre 65° V12 produces 1000bhp

- Maximum RPM – 11,100

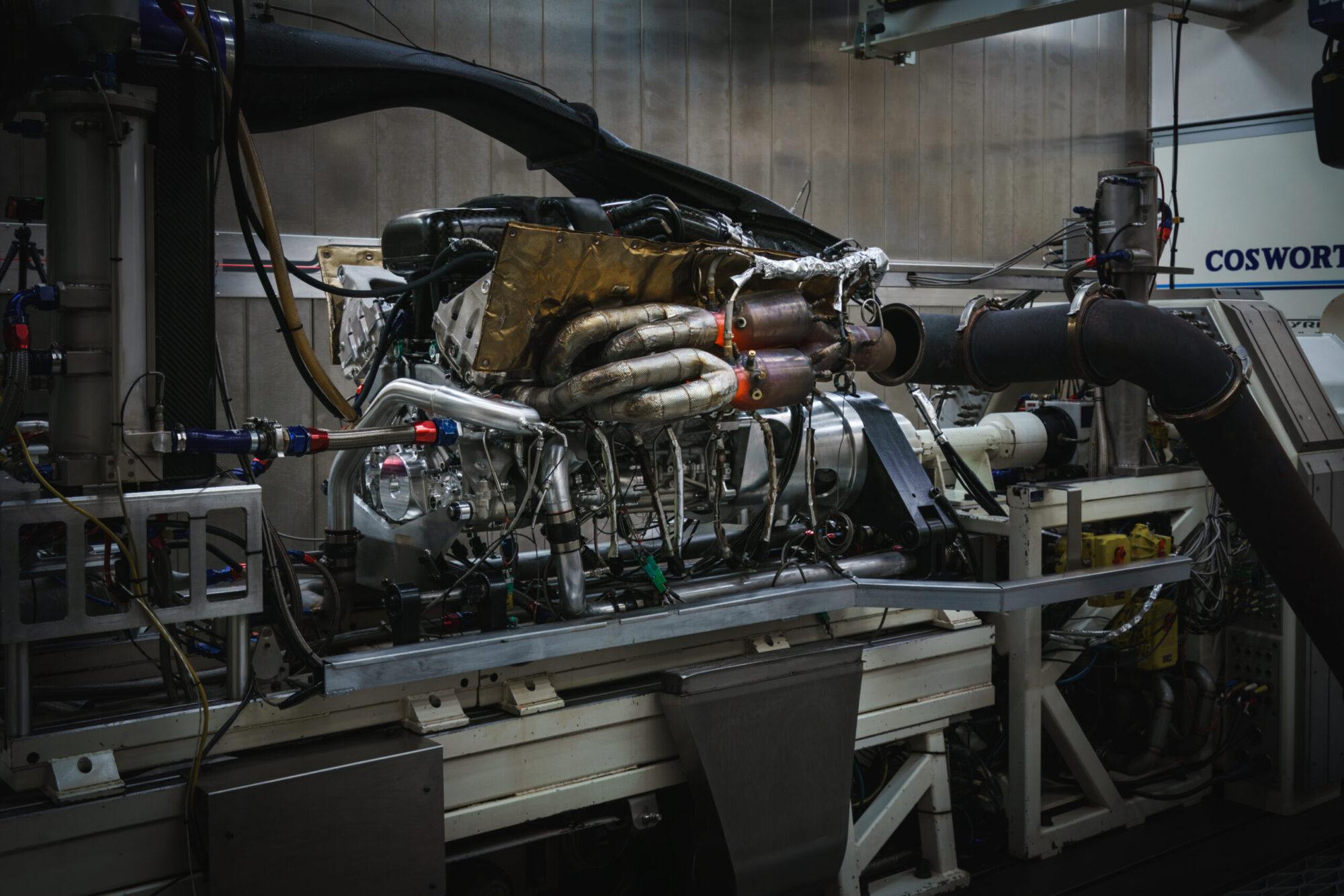

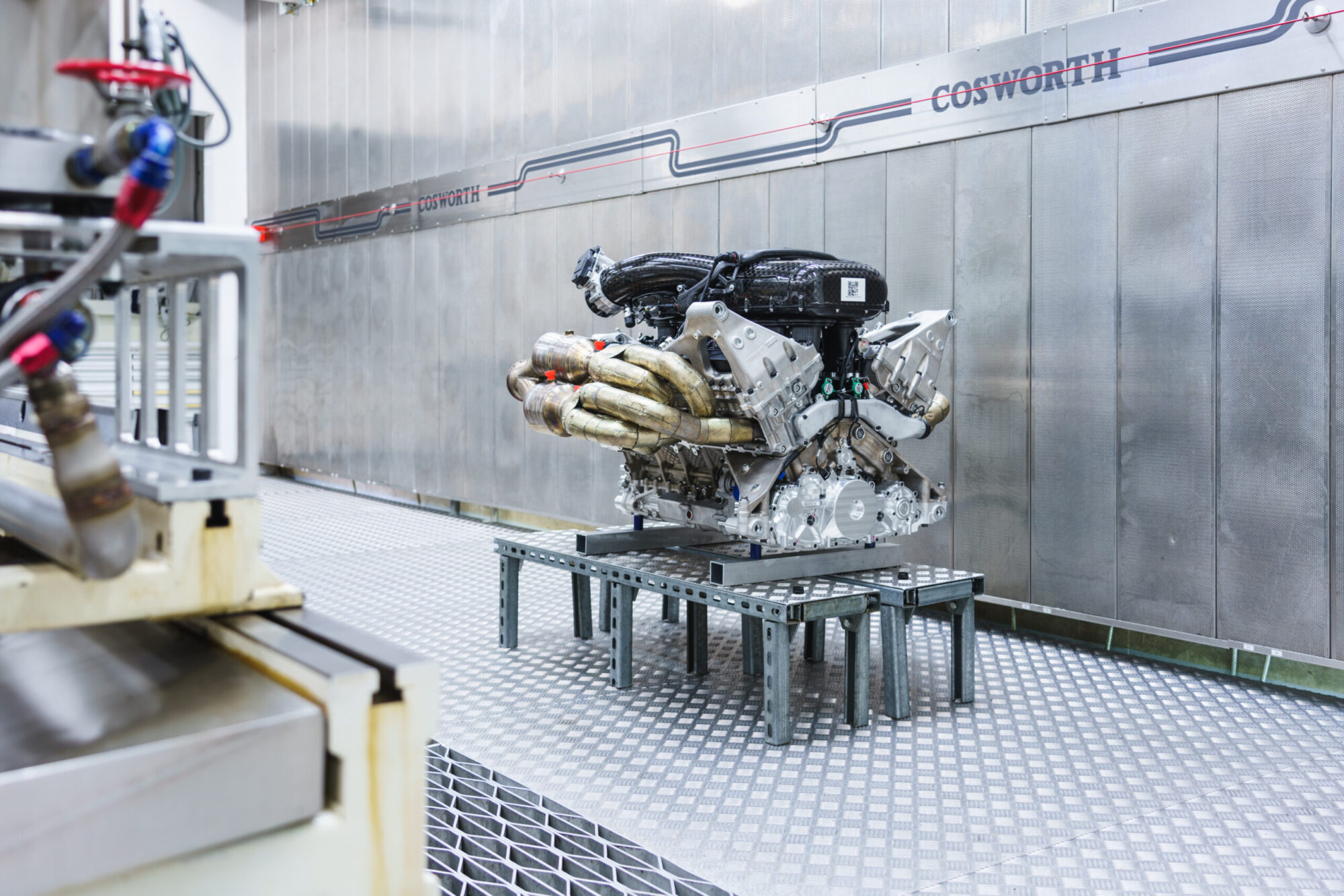

- Developed in conjunction with Cosworth using proven F1 knowledge, materials and methods

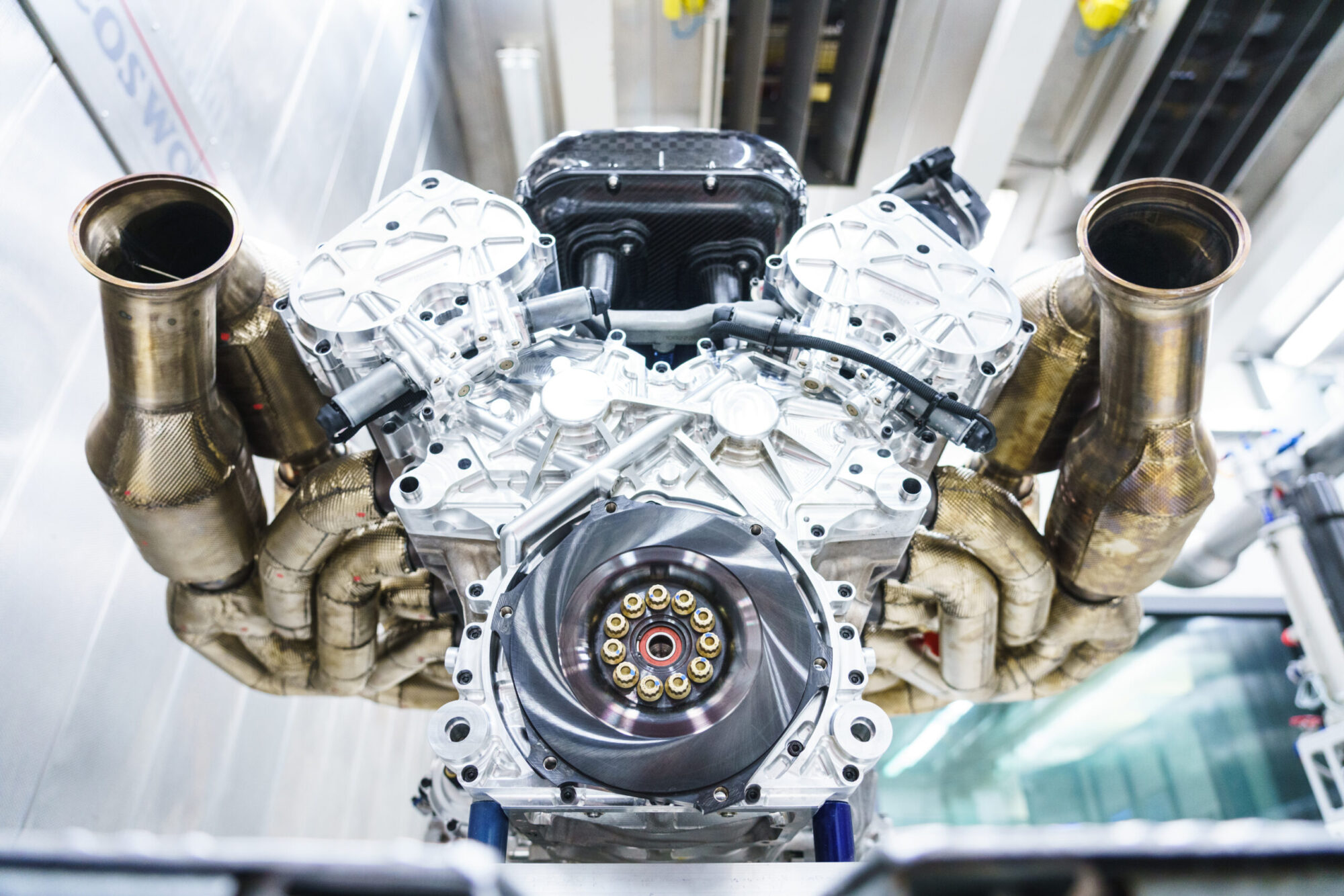

- Engine is fully-stressed element of the chassis, yet weighs just 206kg

- Hits all programme targets for emissions compliance and durability

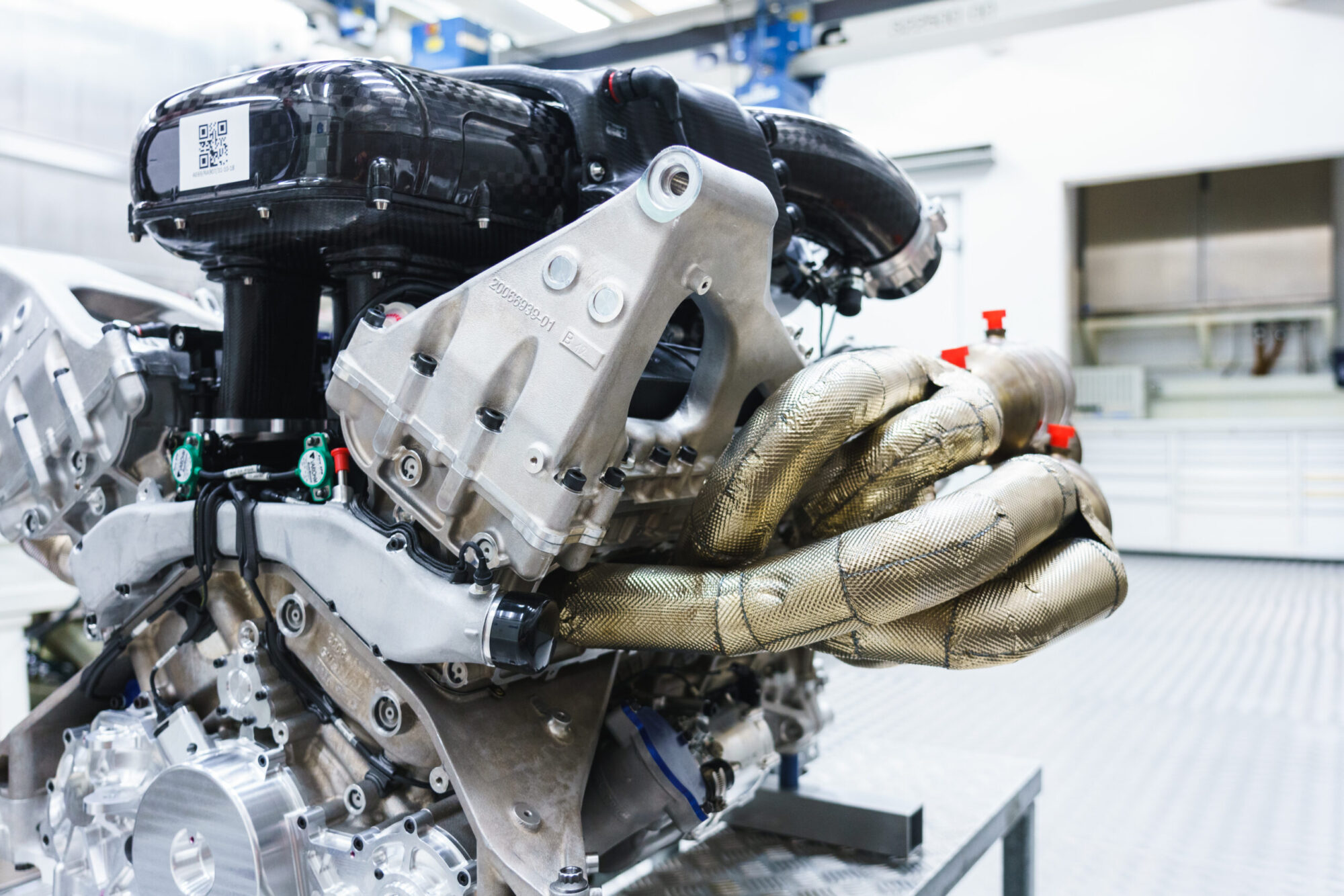

12 December 2018, Gaydon: With development of its new V12 progressing apace the time is right to reveal some closely guarded secrets of the Aston Martin Valkyrie’s extraordinary powerplant. Developed in conjunction with longtime technical partner Cosworth, the new V12 had to satisfy a simple, yet extraordinary brief: to create the ultimate expression of the internal combustion engine.

The programme called for a normally aspirated engine from the very beginning, for while turbocharging has absolutely come of age and offers significant and widespread benefits - especially in a road application - the greatest driver’s car of the modern era demands an internal combustion engine that sits at the absolute pinnacle for performance, excitement and emotion. This means the uncompromising purity of natural aspiration.

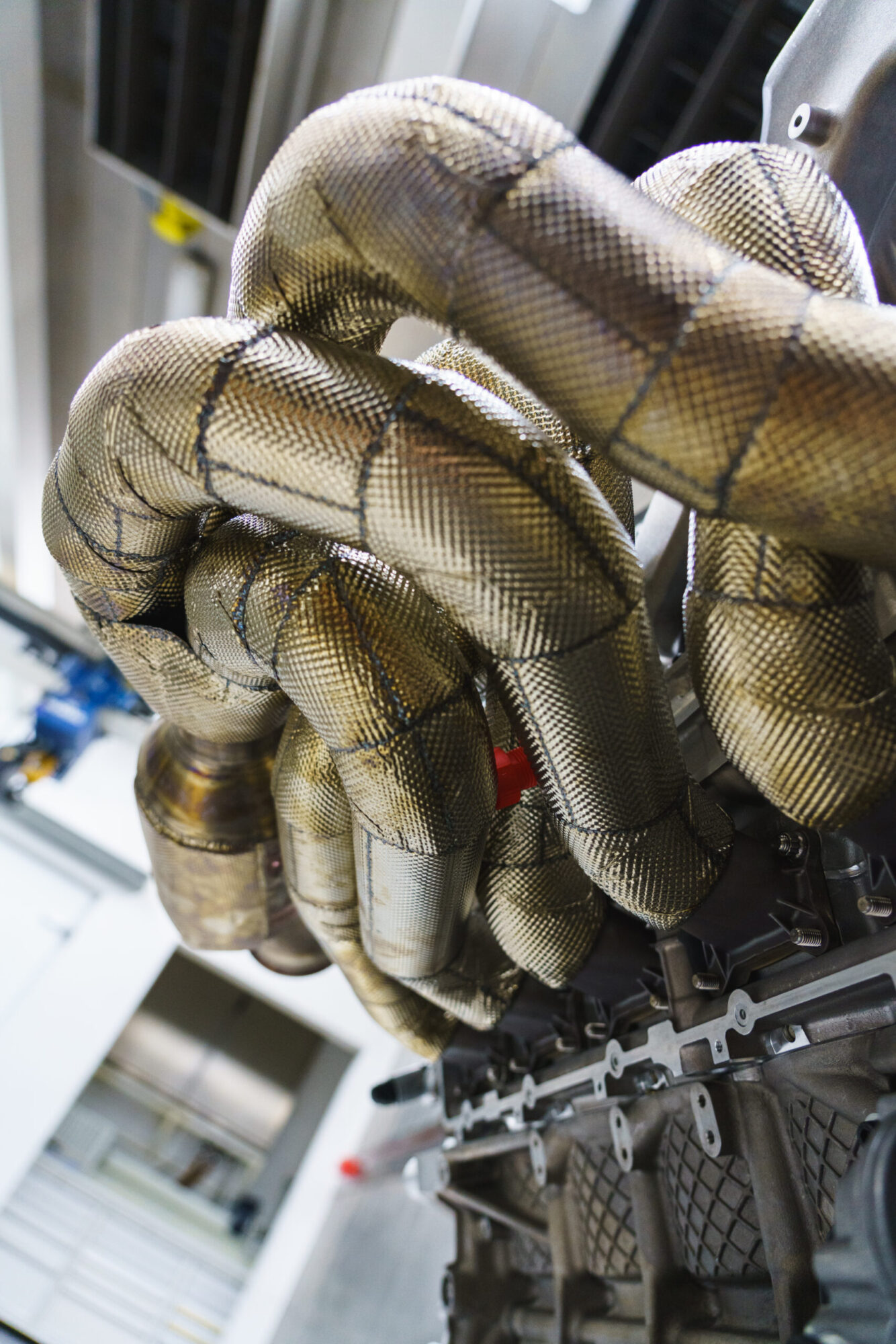

The resulting engine is an absolute masterpiece. Displacing 6.5-litres the 65° V12 sets exceptional new standards for maximum rpm and specific output with a certified peak power output of 1000bhp (or 153.8 bhp-per-litre) at a mind-blowing 10,500rpm, before continuing on to a maximum rpm figure of 11,100: figures that are unprecedented for a naturally-aspirated, emissions-compliant road car application. Peak torque is 740Nm at 7,000rpm. With these peak outputs purely delivered by the ICE (Internal Combustion Engine), Aston Martin Valkyrie’s performance figures will be further boosted by a battery hybrid system, details of which will be revealed later in the development programme.

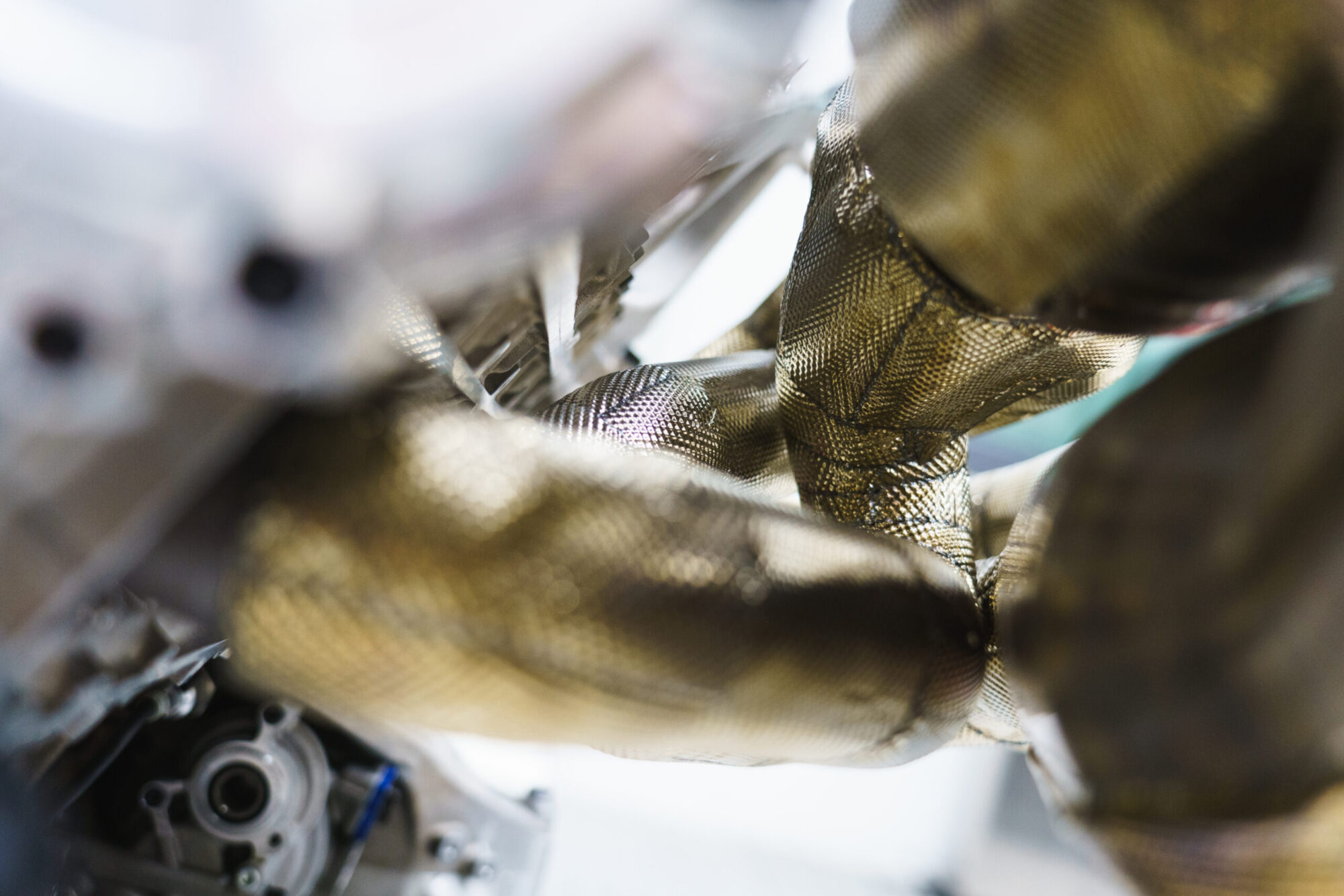

Cosworth’s F1 expertise is also evidenced in the Aston Martin Valkyrie engine’s weight, which also set new standards. Given the engine is a fully stressed element of the car (remove the engine and there is nothing joining the front wheels to the back!) and the level of technology in the combustion system, keeping weight down was a huge challenge. Especially as the programme actively avoided use of extreme materiel alloys which are so new that material properties over time are unproven.

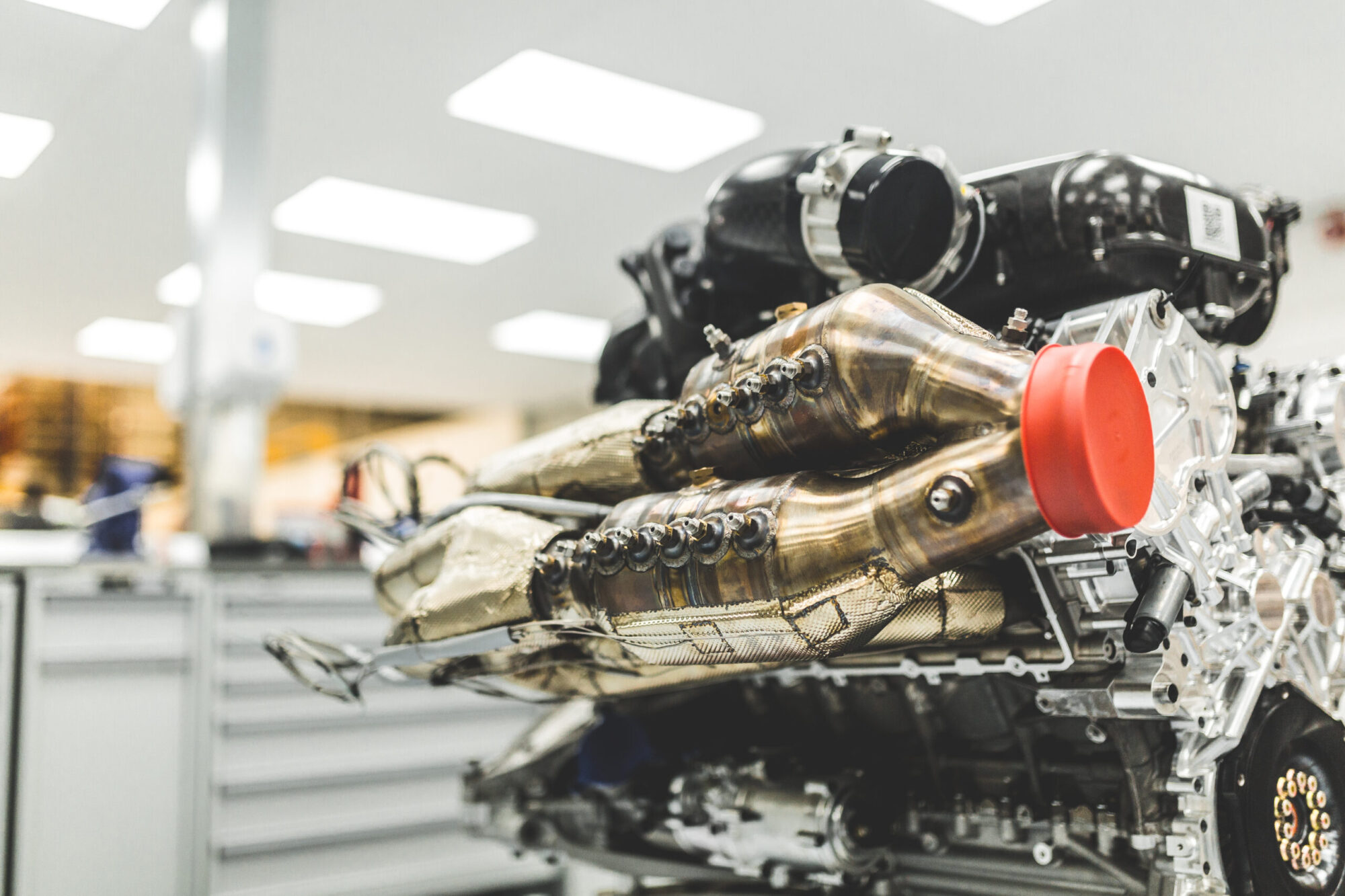

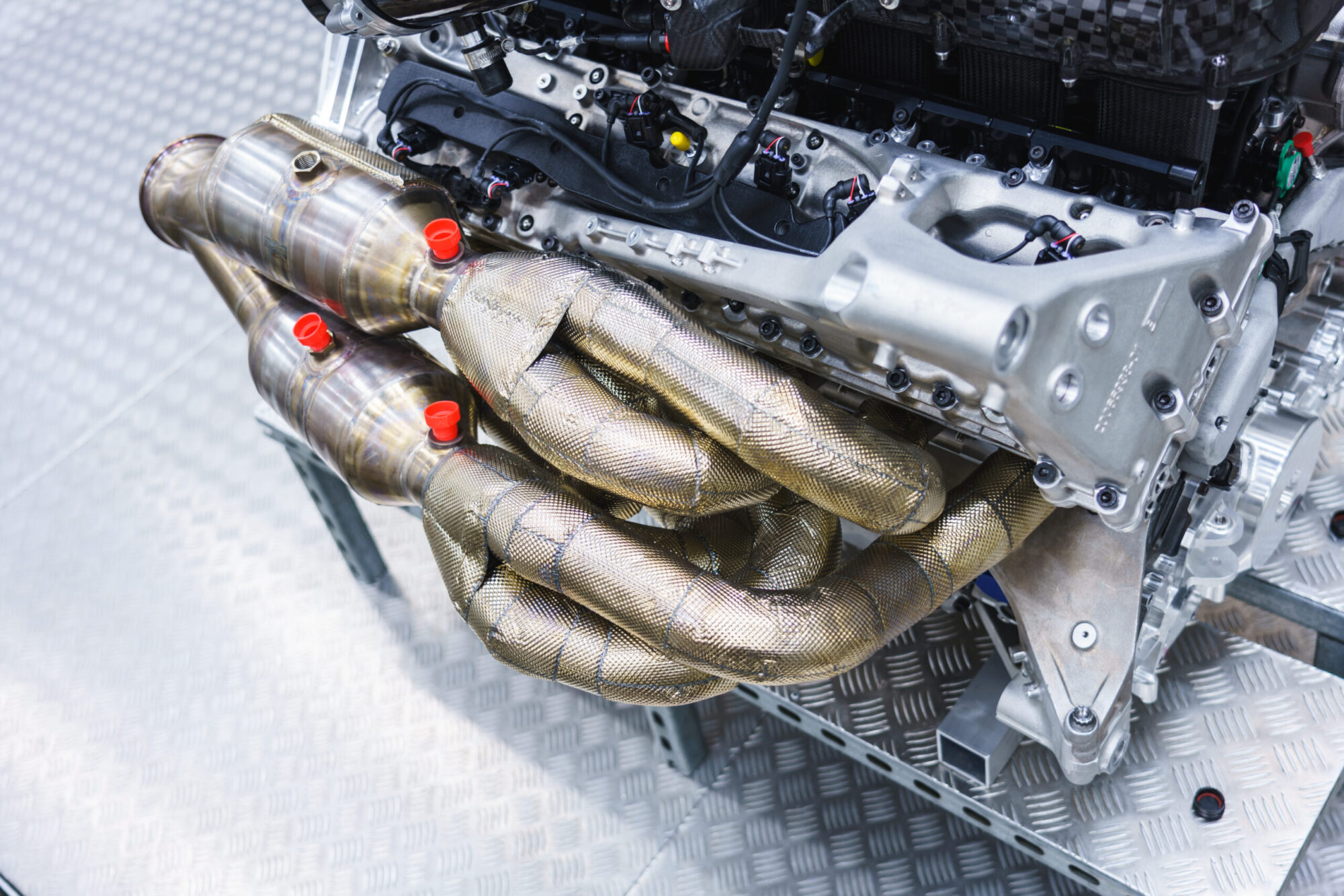

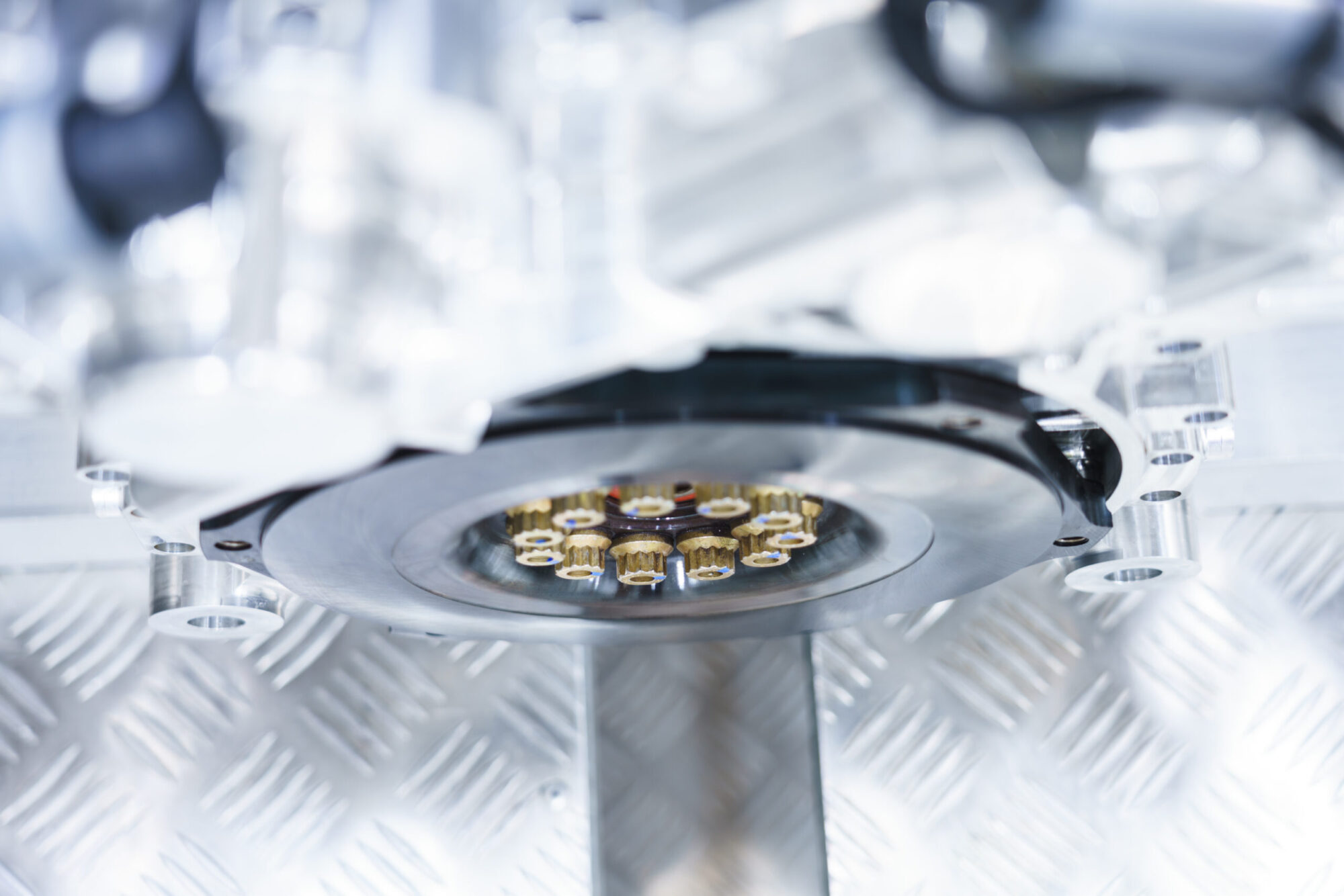

Aside from the major castings - block, cylinder heads, sump and structural cam covers - the majority of the engine’s internal components are machined from solid material. These include Titanium conrods and F1TM-spec pistons. Not only does this allow the use of material with ideal properties, but the ultra-fine machining process means greater consistency and components optimised for minimum mass and maximum strength. The result is an engine that weighs just 206kg. By way of comparison, Cosworth’s 3.0 litre V10 F1TM engines (the last before weight limits were imposed by the FIA) weighed 97Kg. If scaled-up to 6.5 litres this pure race engine would weigh 210kg.

One of the best examples of the painstaking optimisation involved is the billet machined crankshaft. Starting life as a solid steel bar 170mm diameter and 775mm long, it is first roughed out, then heat treated, finish machined, heat treated again, gear ground, final ground and superfinished. Upon completion 80% of the original bar has been machined away and some six months have passed, but the end product is a crankshaft that’s an astonishing 50 per cent lighter than that used in the Aston Martin One-77’s V12 - itself a Cosworth-developed evolution of Aston Martin’s series production V12 and, for a time, the world’s most powerful naturally aspirated road car engine.

Bruce Wood, Cosworth Managing Director, said of the project: “Being asked to create a naturally aspirated V12 engine fit for what will surely be one of the most iconic cars of all time is an immense source of pride for Cosworth. Decades in F1TM taught us to expect a pretty demanding specification from someone with Adrian Newey’s unsurpassed track record, but when we started talking about specifics of power, weight, emissions compliance and durability combined with ever harder and sometimes conflicting targets, we knew this would be a challenge like no other. It’s been a fantastic partnership between Aston Martin, Red Bull and Cosworth with each party bringing a distinct clarity of vision that has proved essential in delivering an internal combustion engine way beyond anything previously seen in a road car application.”

Dr. Andy Palmer, Aston Martin Lagonda President and Group Chief Executive Officer, said of the Aston Martin Valkyrie’s V12 engine: “To anyone with a drop of petrol in their blood, a high-revving naturally aspirated V12 is the absolute pinnacle. Nothing sounds better or encapsulates the emotion and excitement of the internal combustion engine more completely. Despite the apparently insurmountable challenges it presented, there was never any question that the Aston Martin Valkyrie would make do with anything less. From the outset the team at Cosworth were unflinching in their commitment to achieving benchmarks which pushed the boundaries of the possible. The result is a quite extraordinary engine. One which I doubt will ever be surpassed.”

Evoking the spine-tingling, ultra-high-revving F1TM engines of the 1990s, but benefitting from two decades of progress in design, material and manufacturing expertise, the Aston Martin Valkyrie’s 1000bhp V12 is a masterpiece, from one of the world’s most illustrious engine builders: an internal combustion engine without peer for a hypercar without precedent.